MADE IN KAZAKHSTAN. HOW HYUNDAI CARS ARE MADE FOR BELARUS

In just a little while, the people of Belarus will start driving Kazakhstan-made Hyundai cars. The first lot of Santa Fe and Sonata models has already arrived in Minsk from Almaty and will be available in dealerships soon. Belarusian journalists recently visited the Hyundai Trans Kazakhstan plant to see new cars in the making.

It was captivating to see pieces of metal and many small parts turning into a beautiful car. Metal stampings are first welded together to form a body; it is then dipped in a giant bath and painted; this is followed by hundreds of process operations at an assembly line and completed with fluid filling. At the end of it all, a brand-new crossover worth about $40,000 rolls out of the shop to the testing grounds.

Hyundai Trans Kazakhstan is a brand-new plant fitted with state-of-the art South Korean and Japanese equipment. The first car was made at the semi-knock down assembly line in April 2020; the completely knock down assembly line was started last fall and included welding, painting, and over 1,500 different processes in total. The plant is designed to produce up to 45,000 cars a year, of which 50% will be exported to the CIS countries, including Belarus.

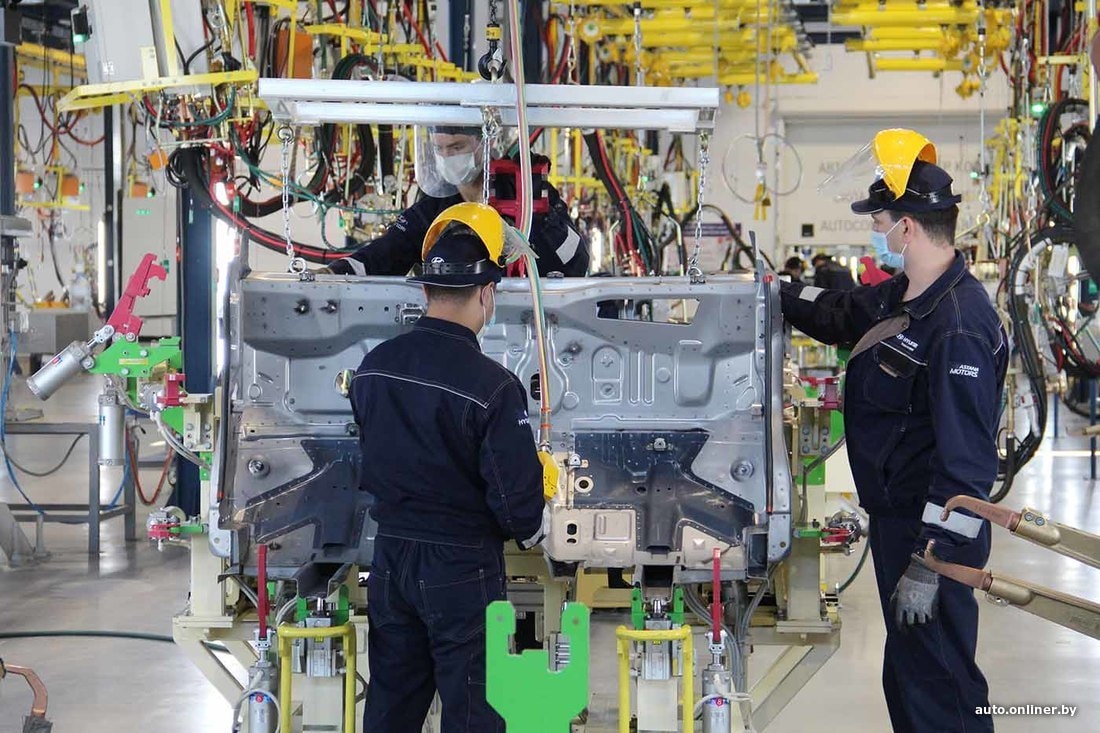

Manufacture of a car starts in the welding shop. Different stampings are supplied to an assembly site to become a full-fledged body. Sidewalls, a roof and other elements are welded to the bottom. The VIN code, doors, a trunk lid and a hood are attached to the car. All of the processes are done by people rather than robots as, for example, at the BelGee plant in Borisov.

“A robotized line becomes economically viable with an output of more than 70,000 cars a year,” says Maksim Tarasov, Director of the plant. “In phase one, we are planning to turn out 30,000 cars a year by the end of 2021.”

After welding, one body from the lot goes to a control station. A dedicated machine checks the geometry and quality of welds at 800 points. The complete check lasts 8 hours; the rule is that if a specimen meets the standard for less than 95%, the entire lot gets rejected.

“The most important thing is to avoid poor quality. There are more people in the quality control department than in the welding shop,” says the Director.

After the welding shop, a body goes to the painting shop. This is a limited access area. The journalists are given special robes and pass through a ventilating hood to blow away any dust particle.

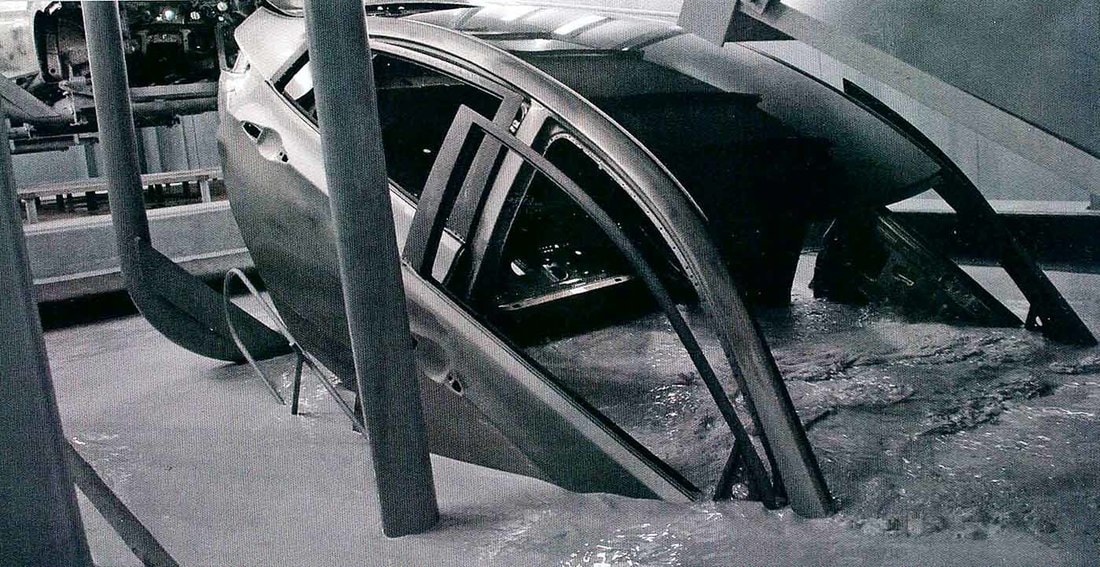

Before painting, the body is cleaned, degreased, phosphatized and then dipped in cataphoresis baths for corrosion protection. There are 14 baths in the shop: 9 at the preparation line (cleaning, washing, activating, phosphatizing) and 5 at the cataphoresis line.

This is followed by drying the cataphoretic coat. The body is kept in a drying oven for 30 minutes at 180 degrees, and then sent to a putty site. In the painting shop, the body is primed and dried. It is then painted and varnished. After the final quality control, the painted body is sent to the assembly shop.

The final stage is assembly. At this stage, car interior and all internals are installed in about 1,000 different operations. After all parts have been assembled, the car is filled with antifreeze, oil, braking fluid and other fluids.

The assembled car goes to the quality control station for a check of tire geometry, the braking system and headlight adjustment. The car undergoes a separate waterproofing test.

The only thing left is the test drive. The new car is tested at the testing ground of the plant. The test includes acceleration, hard braking, and driving over irregularities simulating a bumpy road. If there is nothing that knocks or screeches, and all systems are healthy, the car is sent for final inspection and then to the finished product warehouse.

The plant was designed to export 50% of its products to the CIS countries. Contracts were previously entered into with Uzbekistan. Now Kazakhstan-made DKD Hyundai cars will be supplied to Belarus. The first lot included 40 restyled Santa Fe cars (we have recently reviewed this model): 18 units with an air-breathing 2.5 MPI (180 hp) engine, 6 units with a 3.5 MPI V6 (249 hp) engine and 16 units with a 2.2 l (199 hp) turbocharged diesel engine. 8 Hyundai Sonata cars will also arrive to dealerships.

More than 500 cars are expected to be supplied from Kazakhstan to Belarus by the end of the year. Those will include the Santa Fe, the Elantra, the Sonata and the Tucson.

Source: auto.onliner.by